ARDL’s shelf life prediction capability determines how long a product or component can age in storage and still remain fit for use in service conditions. This time period is calculated by measuring the amount of degradation that occurs during the aging process. Predicting shelf life helps improve the fundamental understanding of chemical mechanisms at work in aging polymers.

ARDL’s service life prediction service is based on innovative testing and analytical techniques to predict the life of a product or component in actual service conditions. Predicting service life enables you to understand and benchmark product life cycles in the field.

Predictive Testing for:

Failure and Fatigue Resistance on: Belts, Engine Mounts, Gaskets, Hoses, Oilfield Packers, Seals, Shaft Seals, Tires, Wiper Blades and More

- New Product Design – Structural and Material

- Shelf Life of Products

- Service Life of Engineering Parts and Medical Devices

Using the Combined Techniques of:

For Shelf Life Prediction:

- Arrhenius Techniques (Based on Accelerated Aging)

- Diffusion Limited Oxidation Model

- Statistical Life Prediction Approach

- Ultrasensitive Oxygen Consumption Measurement

For Service Life Prediction:

- Dynamic and Vibration Study For Service

- Field and Laboratory Data Correlation

- Finite Element Analysis

- Fracture Mechanics

- Physical, Chemical and Thermal Analysis (FTIR, NMR, GC/MS)

- Temperature Sweeps and Strain Sweeps

- Time-Temperature Superposition (WLF) Methodology

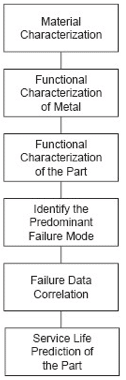

ARDL’s methodology flowchart is shown to the right. The first step is to define the characteristic(s) of each tire component. Based on the function, a failure criterion is established from an unacceptable change which causes a particular failure. Changes may be in sulfidic crosslink densities, stiffness/modulus (static, impact and dynamic), peel adhesion, tear resistance, etc. The underlying mechanism involved in this change is identified and characterized. The rate of change is then determined by an accelerated laboratory test at different levels of severity and at different time intervals. It is important to keep the accelerated test condition similar to the service condition and perform the test at multiple temperatures higher than the average service temperature.

If you would like more information about Engineering Services please contact our Engineering Department, at (866) 778-ARDL or (330) 794-6600.